CO2 Flood Conformance

Applications include Oilfield and Sequestration of CO2 in both injection and production wells.

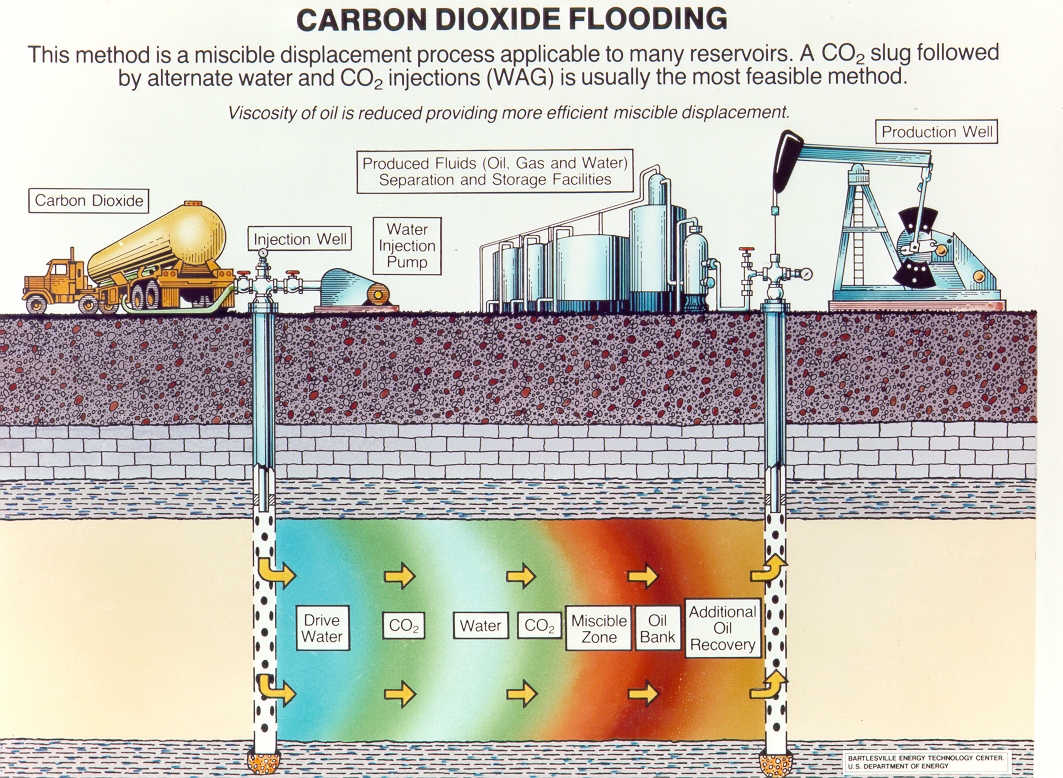

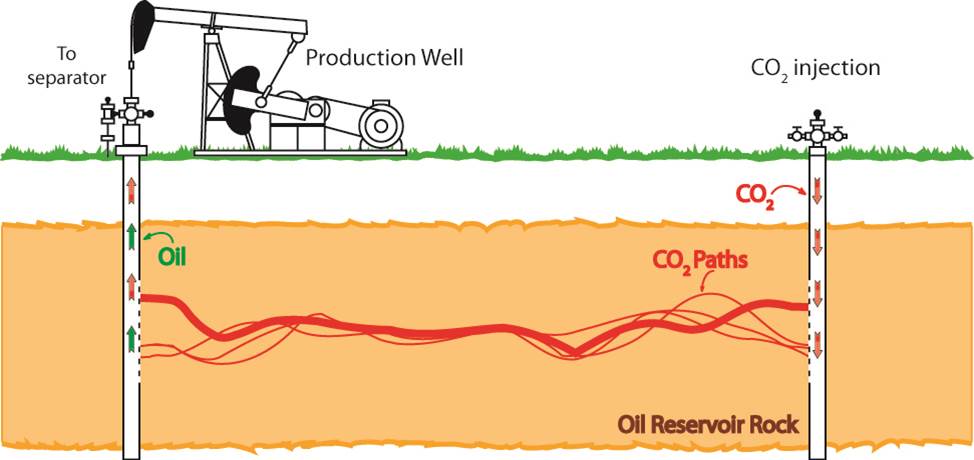

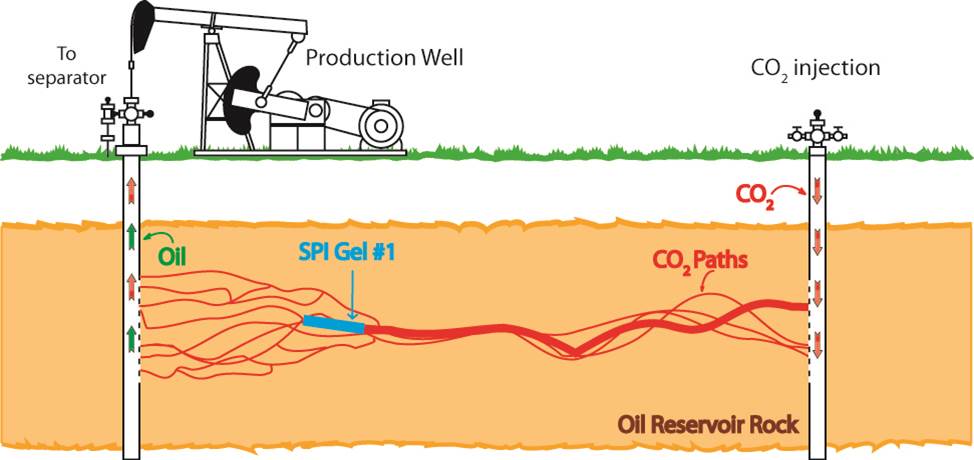

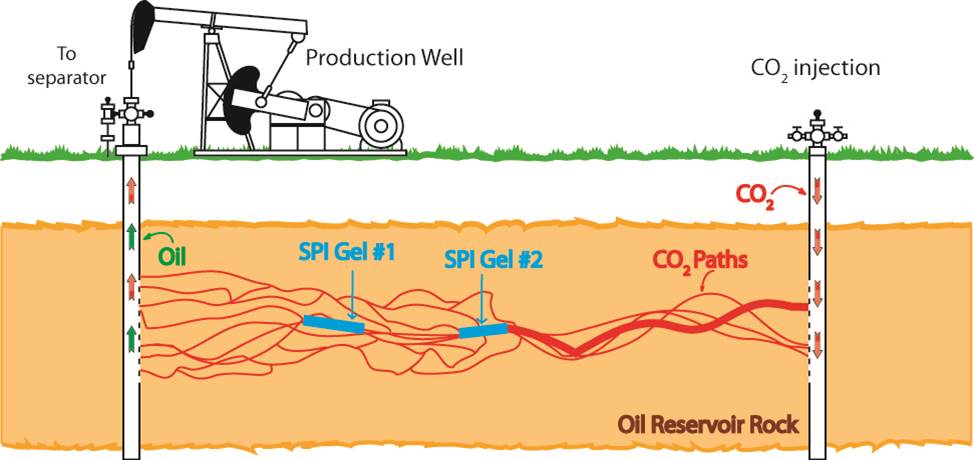

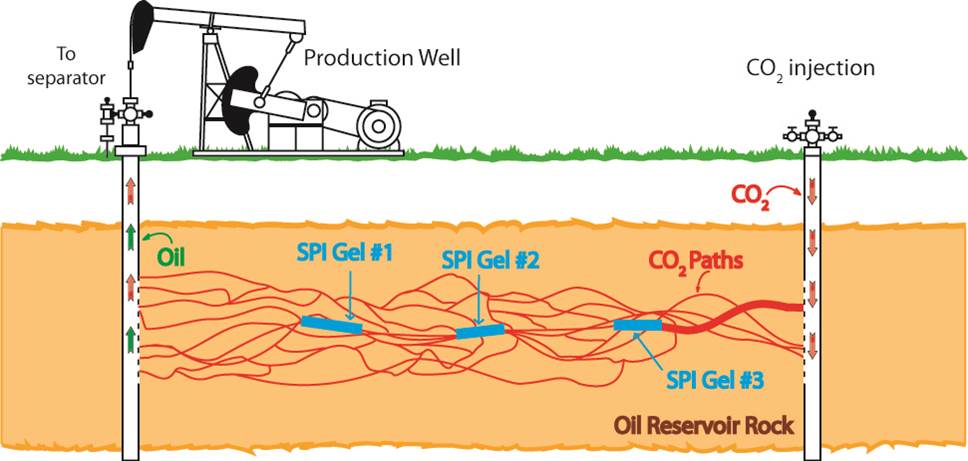

A simplified description of the CO2 Enhanced Oil Recovery (EOR) process can be seen in the DOE website figure below. In this description CO2 is injected into and down one injection well (left) and out into a rock formation. The CO2 gas then uniformly displaces crude oil in the formation by highly efficient miscible and less efficient immiscible chemical actions. These actions dilute and swell the thicker more viscous crude oil and pushes the crude oil to a production well (right) where it is lifted to the surface and sold. However, uniform flow and crude oil displacement does not occur due to the non-uniformity of the rock. The injected CO2 finds the easiest flow path and, over time, stays only in that path without contacting new crude oil- lowering process efficiency and increasing costs. The CO2 is then recycled by cleaning, compressing and re-injecting- an expensive process. Now more than ever, CO2 utilization efficiency and process efficiency are important to lower operating cost. As seen in next figure where multiple SPI gel plugs seal off the highest flow/ permeability/ conductivity paths, the CO2 is forced into previously uncontacted zones where it contacts new oil and displaces it to the production well.

Click here for a larger view. (Source: Department of Energy)

Click here for a larger view. (Source: Department of Energy)

Click here for a larger view. (Multiple SPI treatment option - No Treatment)

Click here for a larger view. (Multiple SPI treatment option - No Treatment)

Click here for a larger view. (Multiple SPI treatment option - One Treatment)

Click here for a larger view. (Multiple SPI treatment option - One Treatment)

Click here for a larger view. (Multiple SPI treatment option - Two Treatments)

Click here for a larger view. (Multiple SPI treatment option - Two Treatments)

Click here for a larger view. (Multiple SPI treatment option - Three Treatments)

Click here for a larger view. (Multiple SPI treatment option - Three Treatments)

Significant lower costs and higher profits can be realized with multiple well treatments in one field utilizing our SPI Gel Technology, to allow optimizing the SPI Gel concentration and mixture size for the most cost effective treatment.

A 2011-2014 US Department of Energy (DOE) project (contract DE-FE0005958) field tested SPI gels in 5 injectors and 1 producer in two CO2 floods. In these tests, the operators were willing to share their data anonymously. The first treatments in 2012 were in a fairly new central Mississippi sandstone CO2 flood. The next set of tests were in late 2013 in a mature west Texas dolomite (San Andres) CO2 flood. Treatment size started small (300-1000 bbls), then the volume was increased to find an optimum treatment volume for the field. Since this was a real field test, other field/ well work was ongoing, but in just 6 wells, each with between 1000 to 5000 bbls of injected SPI gels, the additional recovery during the evaluation period was almost $3MM with some benefit continuing after 9 months. If all of this benefit was due to SPI gels then the return on investment is greater than $150/bbl of SPI gel. However, due to normal field operations, not all of this benefit can be attributed just to the moderate sized SPI gel treatments. Both vertical profile changes and areal conformance changes occurred from these treatments.

Click here for the SPI Final Report to DOE on Project #0005958

SPI gel treatments in injection wells use the injected and reservoir CO2 as the external initiator. Injector treatments take longer to respond than production well treatments. Volumes of water and/or chemicals are used as buffers on both sides of the SPI volume to control the contact/timing of gel formation. Higher injectivity wells have shown the best responses.

SPI gel treatments in production wells use a combination of internal initiators on the tail end of the process and the CO2 already in the reservoir as an external initiator for the lead (front) end. As in injection wells, volumes of water or chemicals are used as buffers on both sides of the SPI volume to control the timing of gelation.

Every reservoir and every well is different. Please contact us to design a SPI Treatment for your CO2 flood wells.